- Home

- About Us

- Inspection Services

- Conventional Non-Destructive Testing

- Ultrasonic Weld Scan

- Ultrasonic Thickness Gauging

- Eddy Current Testing

- Radiography Testing

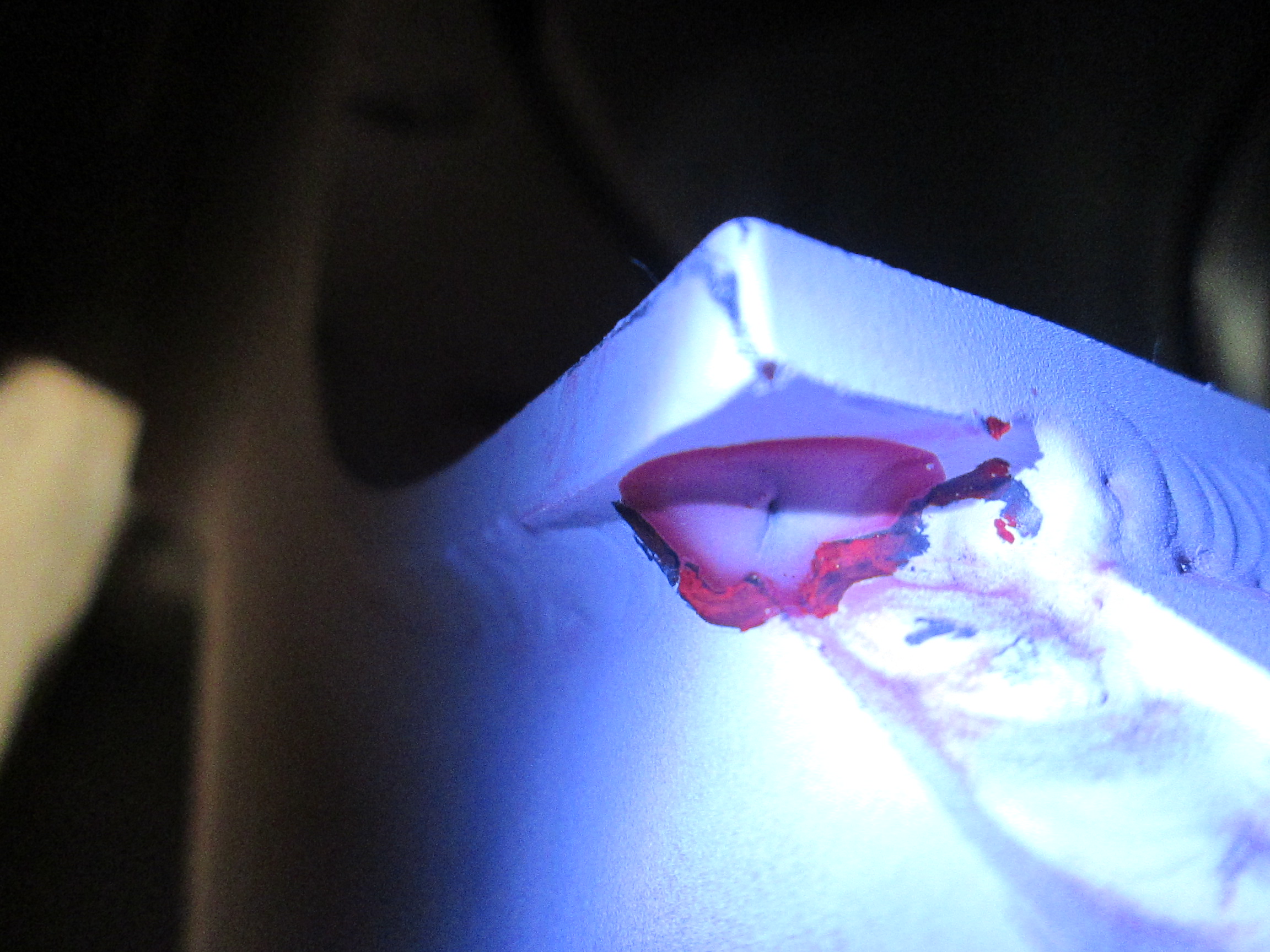

- Liquid Penetrant Testing

- View More

LPI is widely applied as low-cost inspection method used to locate surface-breaking defects in all non-ferrous materials and ferrous materials; although for ferrous components magnetic-particle inspection is often used. LPI is used to detect casting, forging & welding surface defects such as hairline cracks, surface porosity, leaks in new products and fatigue cracks on in-service components. We offer on-site liquid penetrant testing services using contrast or fluorescent penetrant for highly sensitive inspection. We offer on-site liquid penetrant inspection services. For detecting of surface-breaking cracks in non-magnetic materials, we use both color contrast and fluorescent penetrant for highly sensitive inspection.

It is used to inspect metals for surface defects

Weld discontinuities open to surface i.e. cracks, porosity and seams

It can be used on a wide variety of materials: ferrous and nonferrous metals and alloys, fired ceramics,

powdered-metal products, glass, and some types of organic materials

Portable, relatively inexpensive equipment

Expedient inspection results

Results are easily interpreted

Requires no electrical energy except for light source

Indications may be further examined visually

Adapted to volume processing permitted 100 percent surface inspection